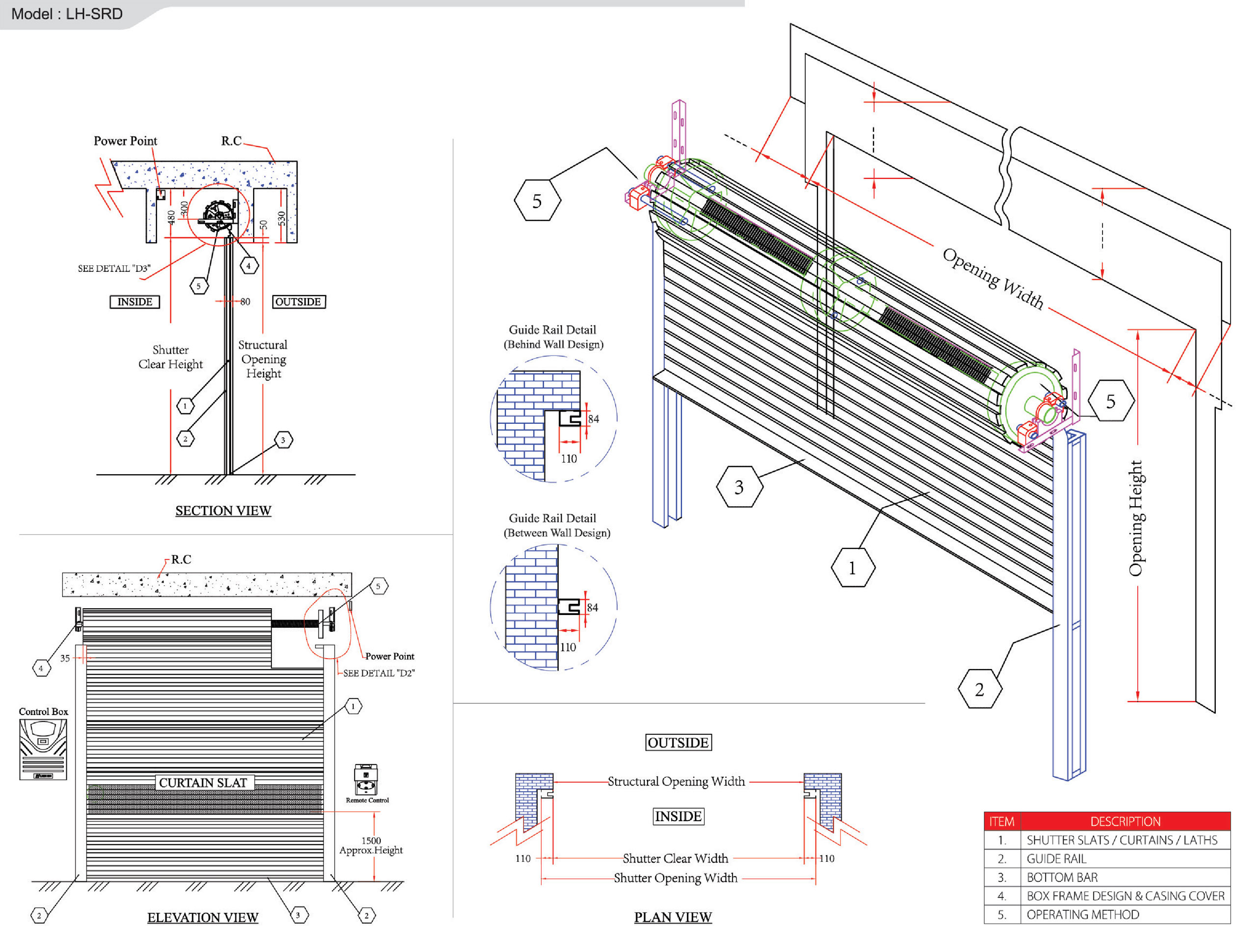

LH-SRD

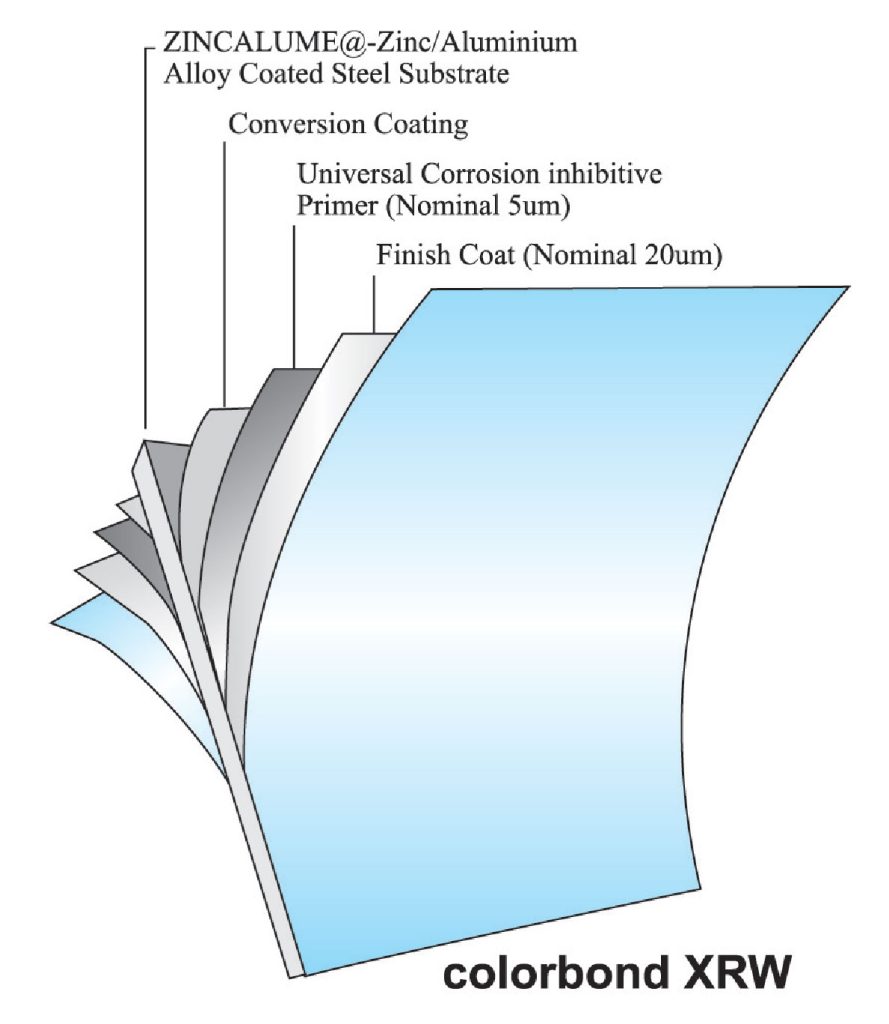

Material Specification

Shutter Curtain

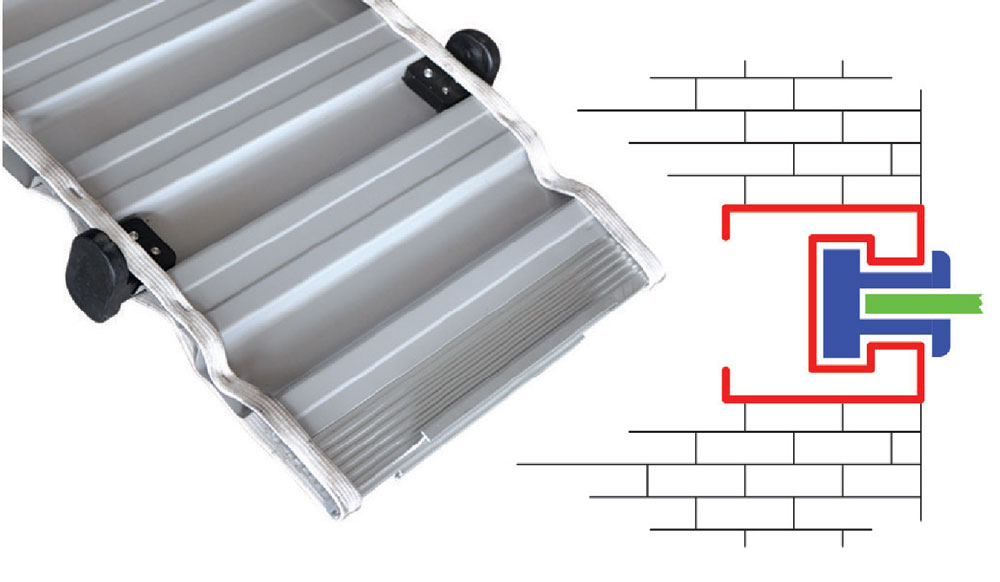

LH-SQ series square shape curtain is computer designed and roll form continuous sheet design with using 0.5mm thick BHP COLOURBOND® / BHP Zincalume® steel sheets. Both side of the curtain covers with wear-resisting rubber belts (which ready for 20 years based on three cycles a day), to prevent metal to metal contact and achieve noiseless & greaseless operation.

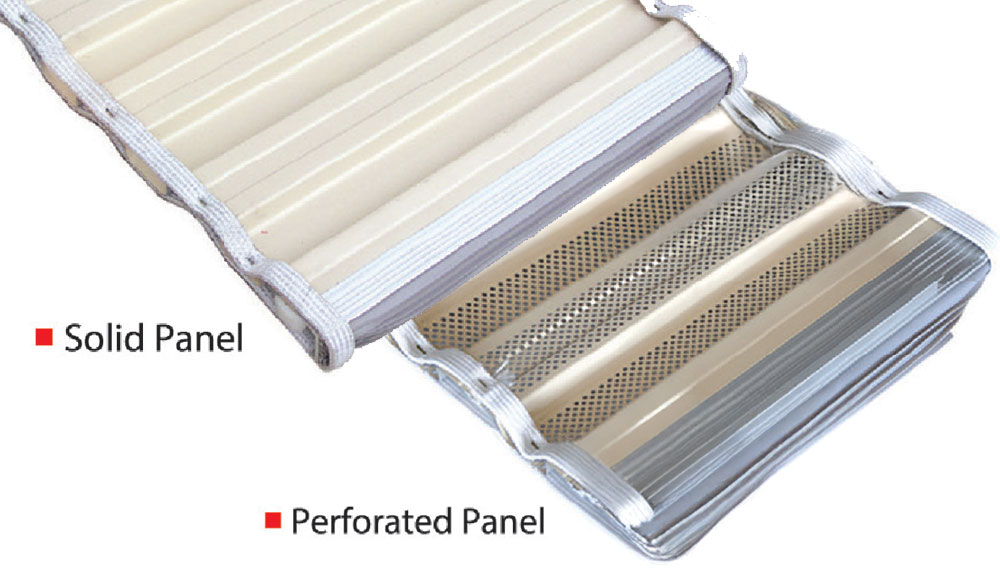

Door curtains pattern available:

- LH-SQSD, Solid continuous steel sheet design

- LH-SQST, Dia 3mm perforation hole continuous steel design

- LH-SQCE, cat eye shape ventilation slot continuous steel sheet design.

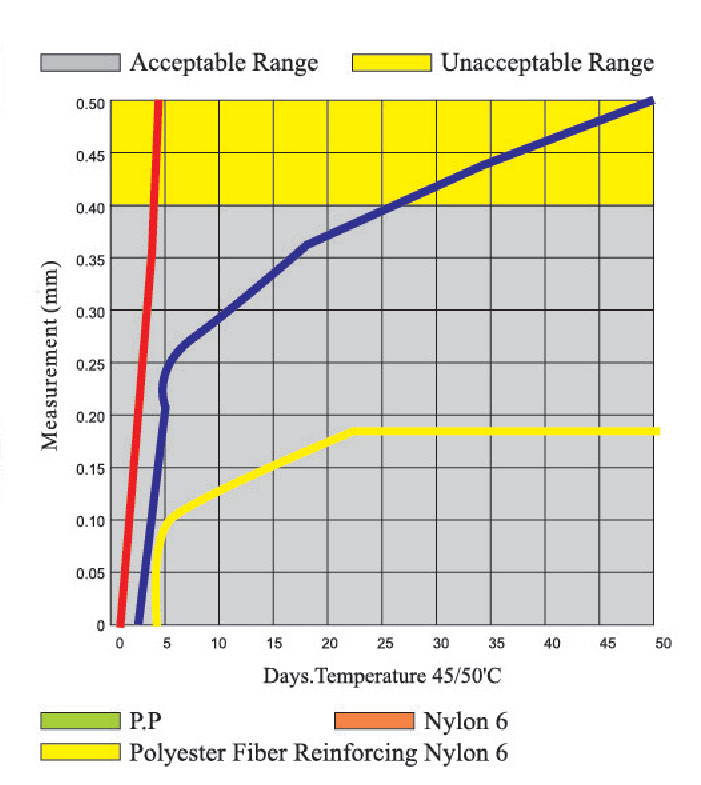

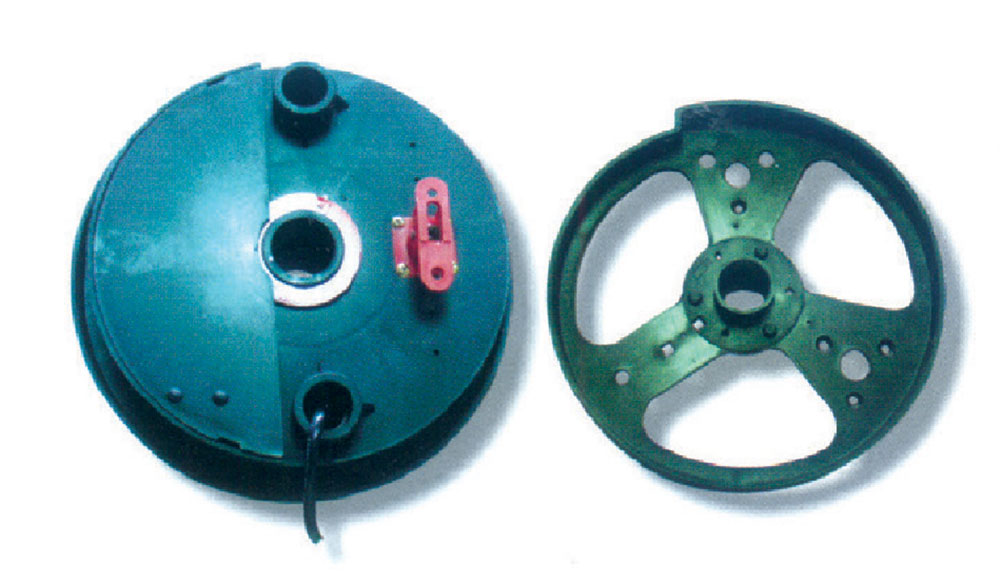

Shutter Drum

Drum assembly shall consist of circular tube mounted with high torsion counter balance spring assembly between high performance engineering plastics drum wheel which usage can upto 15 years base on three cycles a day. Shutter drum is fully wrapped one round by

Bottom Bar

“L” shape section, LH-D012 extruded aluminium (6063-TS) bottom bar is special design come with PVC weather seals fitted on the bottom, purpose is to closed the uneven gap to prevent undesirable material

Guide Rail

Roll form from first grade steel sheets with groove 115mm depth minimum, special design heavy duty box shape LH-Dl 15 (1.0mm thick) guide rails suitable for all type of wall mounted. All designed of guide rails shall be of one piece forming without any joint to achieve maximum rigidity for installation. Material specification a

Optional Items

- Box Cover with Steel Frames

- Car charger accessories

- Max Size:

Manual: 6000mmW x 3500mm HT (Single Panel)

Electrical : 9000mmW x 5000mm HT (Single Panel)

Door Operation

Motor

Hi-Technology 24V DC motor operator with 230 Volt single phase, 13A power input, is specially design for drum design shutter box. With most components in N-8 engineering plastic, the running power is provided by a single 24V DC motor with turn-style gear reduction assist by spring. Automatic light will illuminated for upto 60 seconds after the door is activated. Motor travelling speed is not less than 150mm per second. Motor is completed with build in bottom safety sensor and remote control. Manual mode can be easily converts by pulling the manual release lever mounted at the motor which shutter can easily push up or down by hand manually.

Manual Spring

Safety Design Featues

- Reverse – The door will reverse when the downward movement be restricted.

- Stop – The door will stop when the upward movement be restricted.

- Automatic – Automatic door closing system that in accordance with user’s personal demand. A single remote control can control up to 3 frame doors. Avoiding confusion made by too many remote control.

- Remote Control – No reception of code. Using digital code that incorporates with SAW components.

- Low Voltage – Using DV24V in stead of 110V.

- Fire Prevention – Using COLOR BOND Steel and heat-proof plastics.

- Intruder Alarm – The alarm will sound continuously when the door is accessed by forced by a tangible object.

- Photoelectric Eye – An added safety feature to the door opening or closing when the process is interfered.

- Detector – Can be connected to the fire – fighting system. If there is smoke or carbon monoxide, the door will close automatically to prevent poisoning.

BHP Group Australia & COLORBOND Steel

Established in 1885, the BHP Group Australia (Broken Hill Property) has emerged as the largest company in Australia, employing over 60000 staff. The BBP Group Australia focused on the production offlat steel products, including slab, hot rolled coil, cold rolled coil, plate, tin and value-added metallic coated and painted steel products. John Lysaght (Australia) Pty Ltd, the wholly owned subsidiary the BHP Group Australia, is now the world’s largest metallic coated and painted steel products manufacturer. John Lysaght (Australia) Pty Ltd has already established the market for high quality coat steel products and pioneered modern steel coating technologies.

The Typical Properties of COLORBOND Steel

SUBSTRATE INTENSITY:

Substrate Intensity accords with Australian AS 1397-1903, G300 Grade or ASTM A792-83, 40-50 Grade. Its tensile strength is higher than 3470KG/cm2.

COLORBOND SPECIMEN:

1. The Aluminum-zinc alloy is produced through hot and cool coating processes. The alloy composition: 55% of aluminum, 43.5% of zinc, and 1.5% of silicon. The alloy accords with AS 1397-1093 of Australia and AZl 50 Grade Regulation of surface treatment.

2. Surface treatment -After the Aluminum-zinc alloy is produced, it is roller-coating and heated twice.

– Front: Sum of Epoxy Primer, Sum of Silicon Polyester outside, total 25um.

– Back : Sum of Epoxy Primer, Sum of Silicon Polyester outside, total 1 Oum.