LH-PRS

Material Specification

Shutter Curtain

LH-C00SST See Thru Perforation hole Slat

Roll formed from first grade BHP Zincalume® steel / high quality phosphate galvanized steel, punch with Dia 3mm/Dia 5mm perforation hole with reinforced interlocking groove to achieve maximum holding strength to each interlocking lath. Design curtain to be “LH-C008ST”. Material specification accordance to JIS G3313 SECC-PHOSPHATED.

LH-C00SV / LH-AL012V Ventilation Slot Slat

Roll formed from first grade BHP Zincalume® steel or high quality phosphate galvanized steel “LH-C008V” or T6065 Extruded Aluminium Slats “LH-AL012V”, punch with 300mmWx30mmHTVentilation slots with reinforced interlocking groove to achieve maximum holding strength to each interlocking lath. Design curtain to be “LH-C008V” or “LH-AL012V”. Material specification accordance to JIS G3313 SECC-PHOSPHATED, or, Extruded Aluminium material 6063-TS.

LH-RG Roller Grille

“LH-RG” is combine of Dial 0mm extruded aluminium round tube link by Dial 0mm MS solid bar and 2.5mm thick extruded aluminium double link to achieve maximum holding strength to each interlocking row. Material available Extruded Aluminium material 6063-TS or Stainless Steel finish.

Bottom Bar

LH-T012 G.I. Bottom Bar

Fabricate from two pieces first grade hot dipped galvanised steel angles of 38mm x 38mm x 3mm thick bolted together as T-shape section, both end with plastic end cap fixing for smooth operation. Material specification to JIS G3302 SGCC.

Side Guides

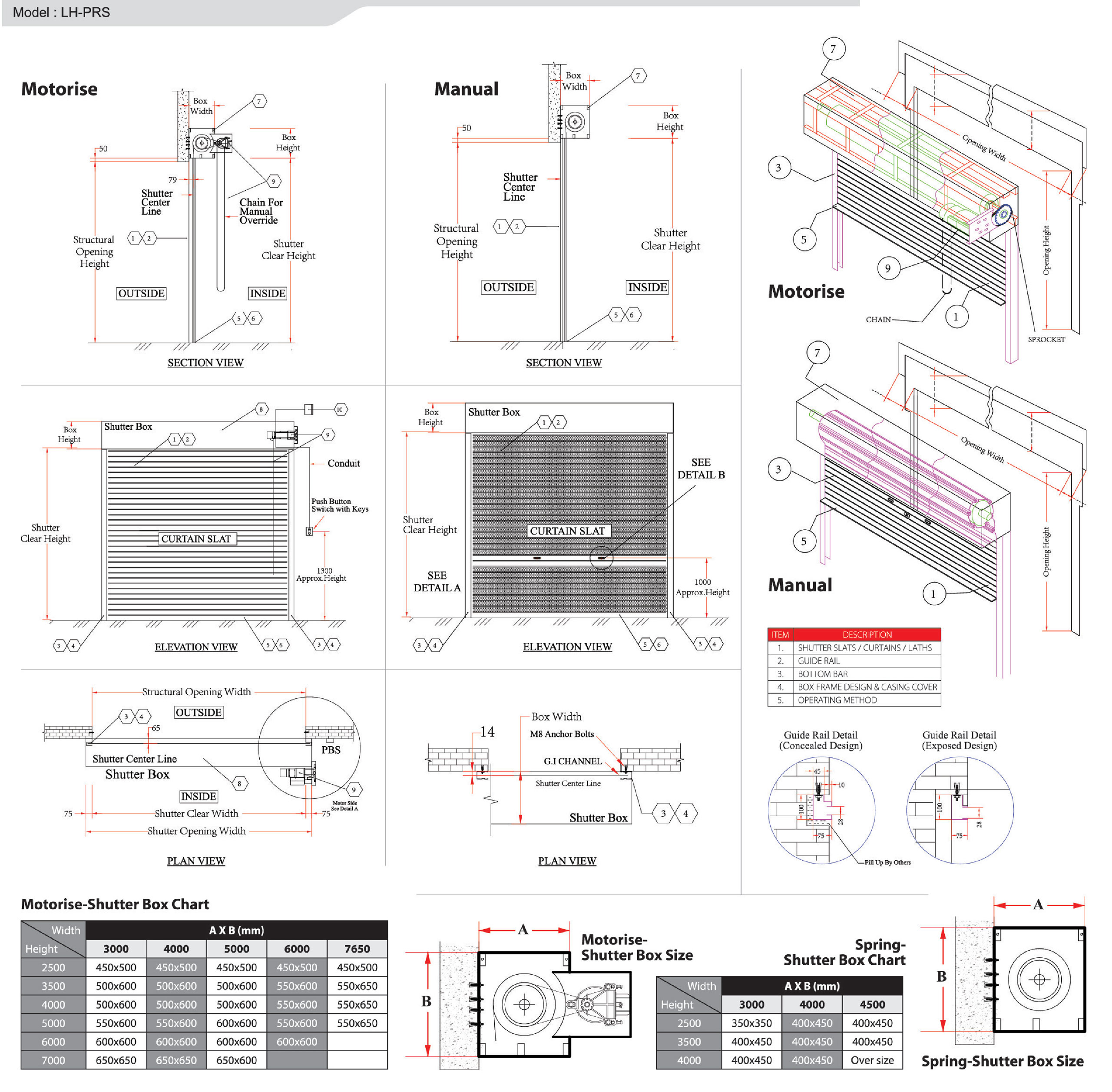

LH-F020 / LH-F025 / LH-M015 G.I. Guide Rail

Fabricated from first grade steel sheets with groove about 75mm depth. Concealed to wall type design LH-M015 (1.5mm thick) and exposed face fixed type design LH-F20 (2.0mm thick) or LH-F25 (3.0mm thick). Material specification accordance to JIS G3302 SGCC-ZSCV Z 18.

LH-F028 Extruded Aluminium Guide Rail

Special design LH-F028 extruded aluminium 6063 TS heavy duty surface mounted guide with Silenser belt. Strong and rush proof, greaseless and low noise. Material specification extruded aluminium 6063-TS.

Shutter Box

Fabricated from first grade steel hollow sections with galvanized steel sheets covers with corner folded edge to achieve maximum strength, minimum thickness of 1.2mm of minimum size 25mm x 50mm or 38mm x 65mm welded to the heavy duty end plate of minimum of 6.8mm thickness.

Drive Barrel

Fabricated from British Standard Welded Steel Pipes BS 1387 or JIS G3452 with both sides solid steel shafts supported by enclosed bearings to both heavy duty end plates. All drive shafts shall be of solid steel shaft in single piece and fabricated from two heavy duty flange as standard and fully welded to the edge of barrel steel pipe both end.

Shaft Support

All support bearing and bearing housings shall be design with bolted to the heavy duty end plate at both side. Welding of bearing housing to the endplate design is not allow. Each bearing’s housing must provide with 4 pieces of bolts and nuts tightened to the end plates as standard.

Operation Control

The control for opening and closing of shutters by means of 3 ways push button switch. Each motor is equipped with built in thermal protector, reduction speed gear box, manual override chain when power failure occurs, limit switches for setting upper and lower limit of shutter travel, minimum design of insulation class E, built in release level for gravity close as standard. Power source available in 230v single phase and 41 Sv three phase S0Hz. Selection of power source according to manufacturer standard for various size of shutter door opening width and height.

Finishing

Available in natural Zincalume® steel, Bhp colorbond steel, galvanized iron, stainless steel. NA Aluminium Finish; Shutter curtains, bottom bar, guide rails, mullions, casing covers available in powder coated finishing, colors subject to manufacturer standard color (RAL color code). Powder coated finishing on steel are tested accordingly to the impact, hardness, adhesion and flexibility bend. (Certificate available upon request only.)